- Home

-

About Us

About Us

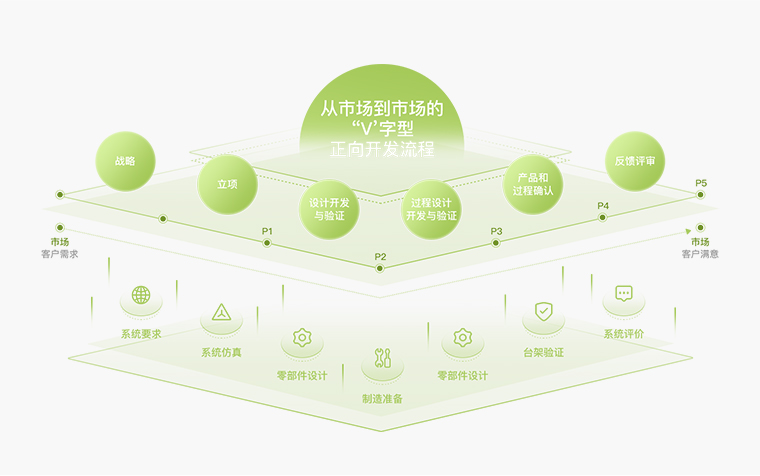

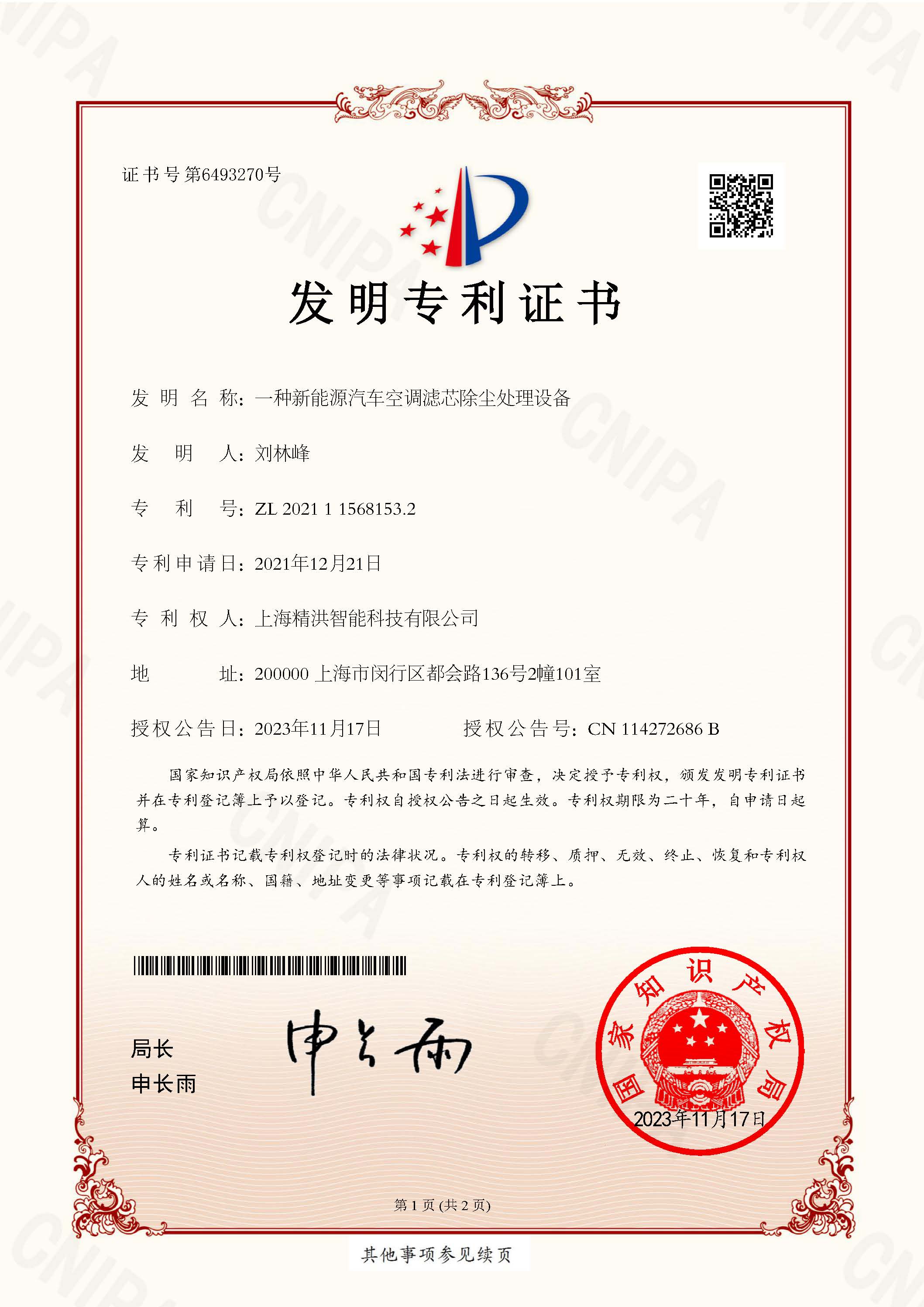

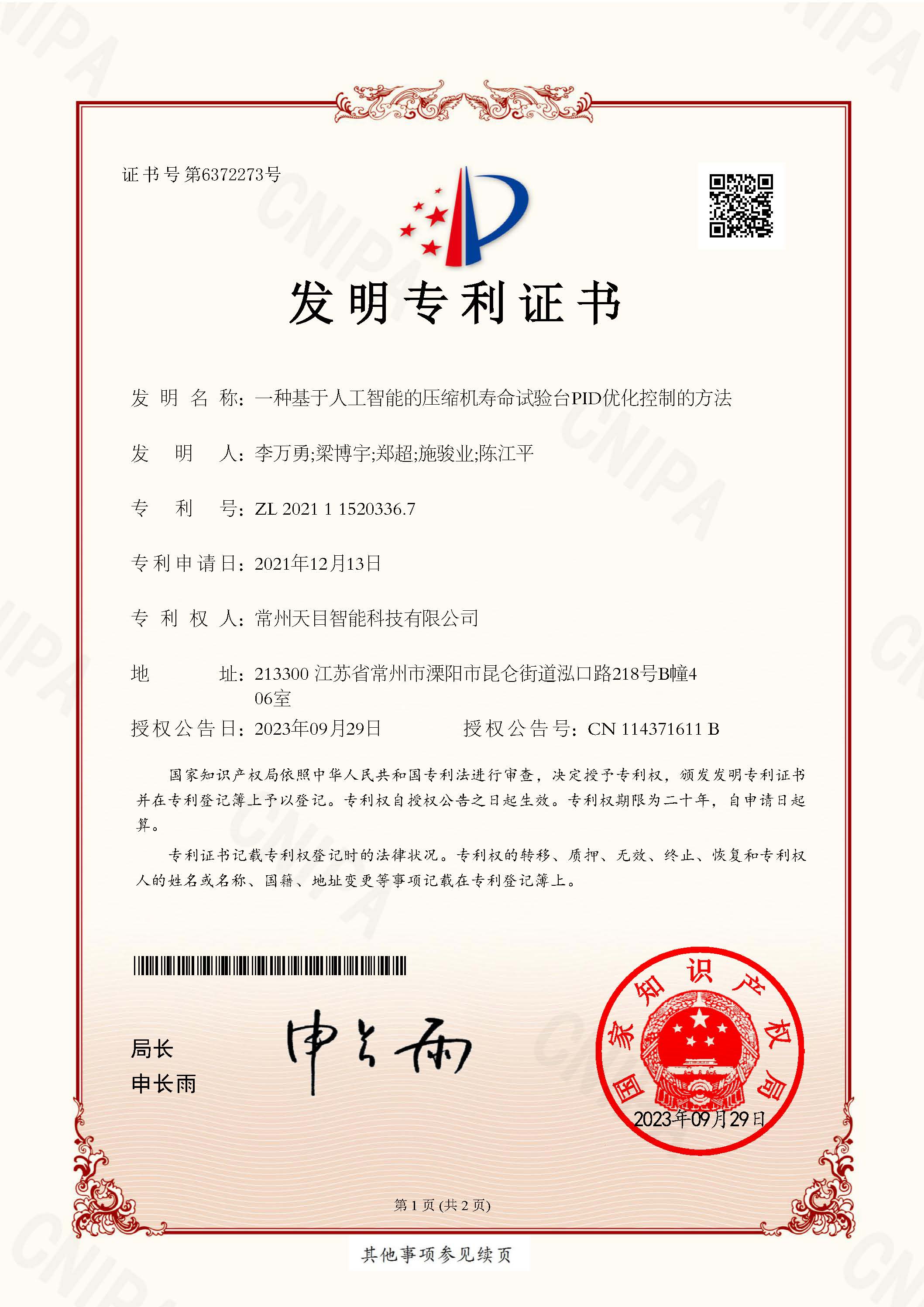

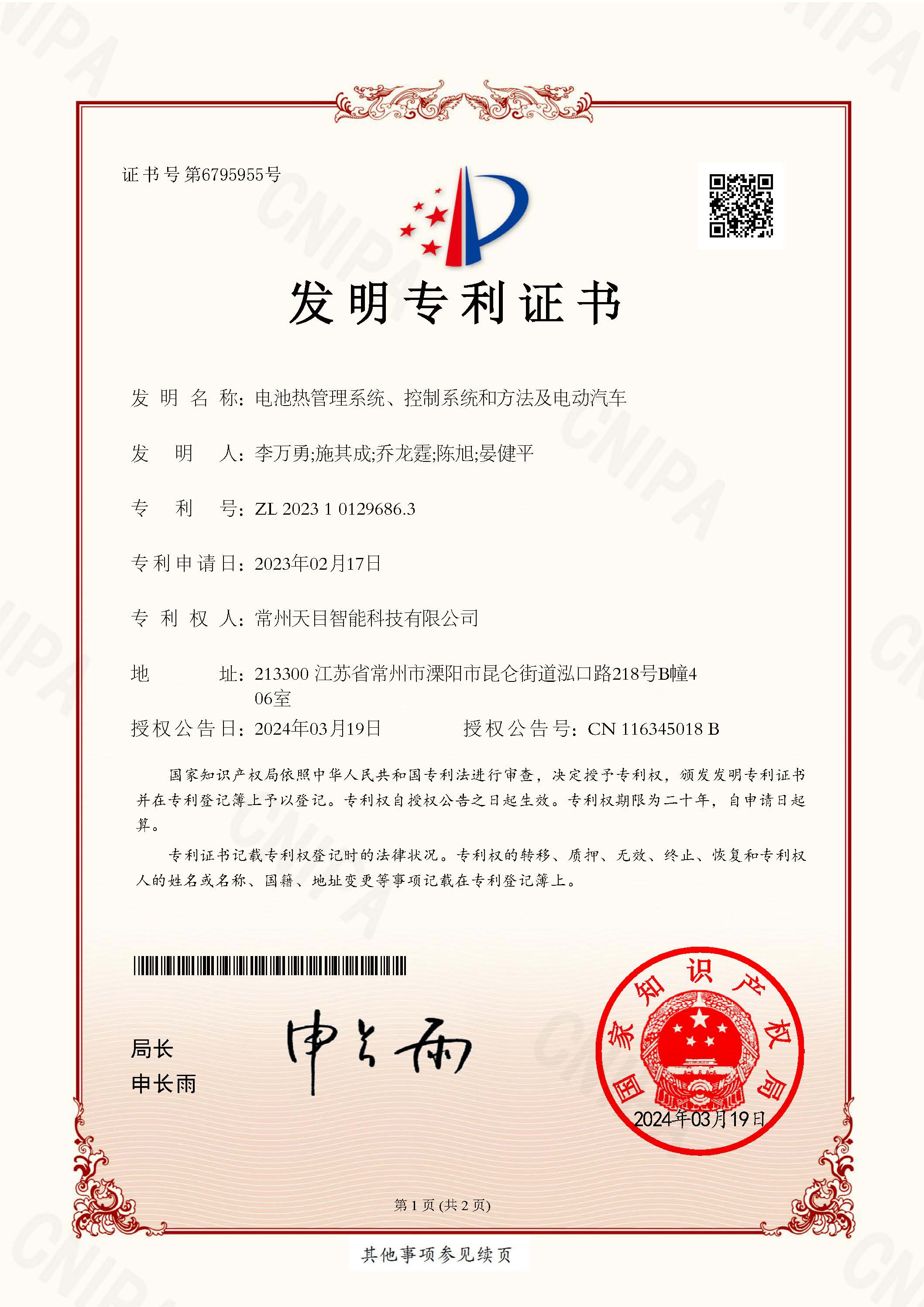

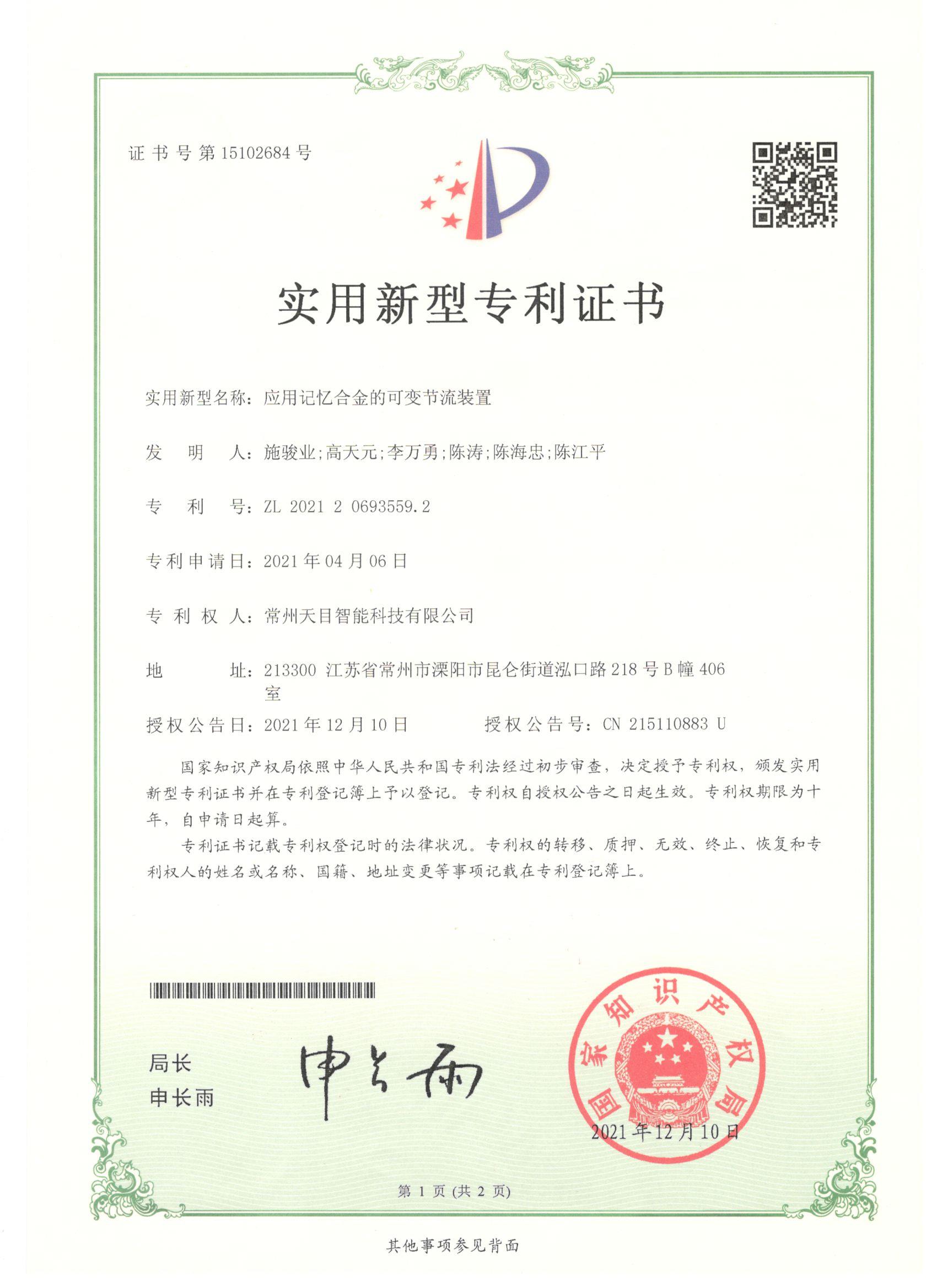

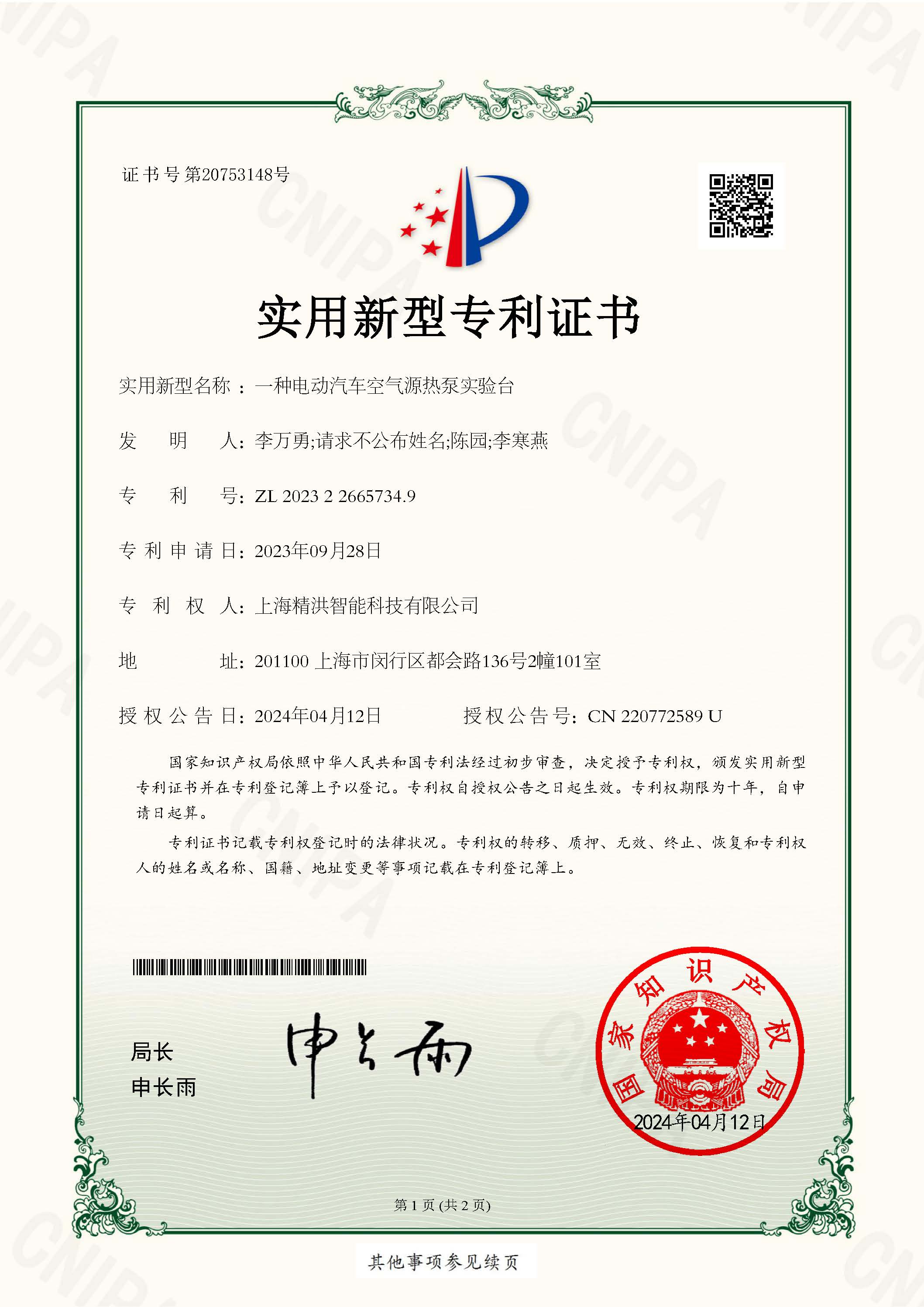

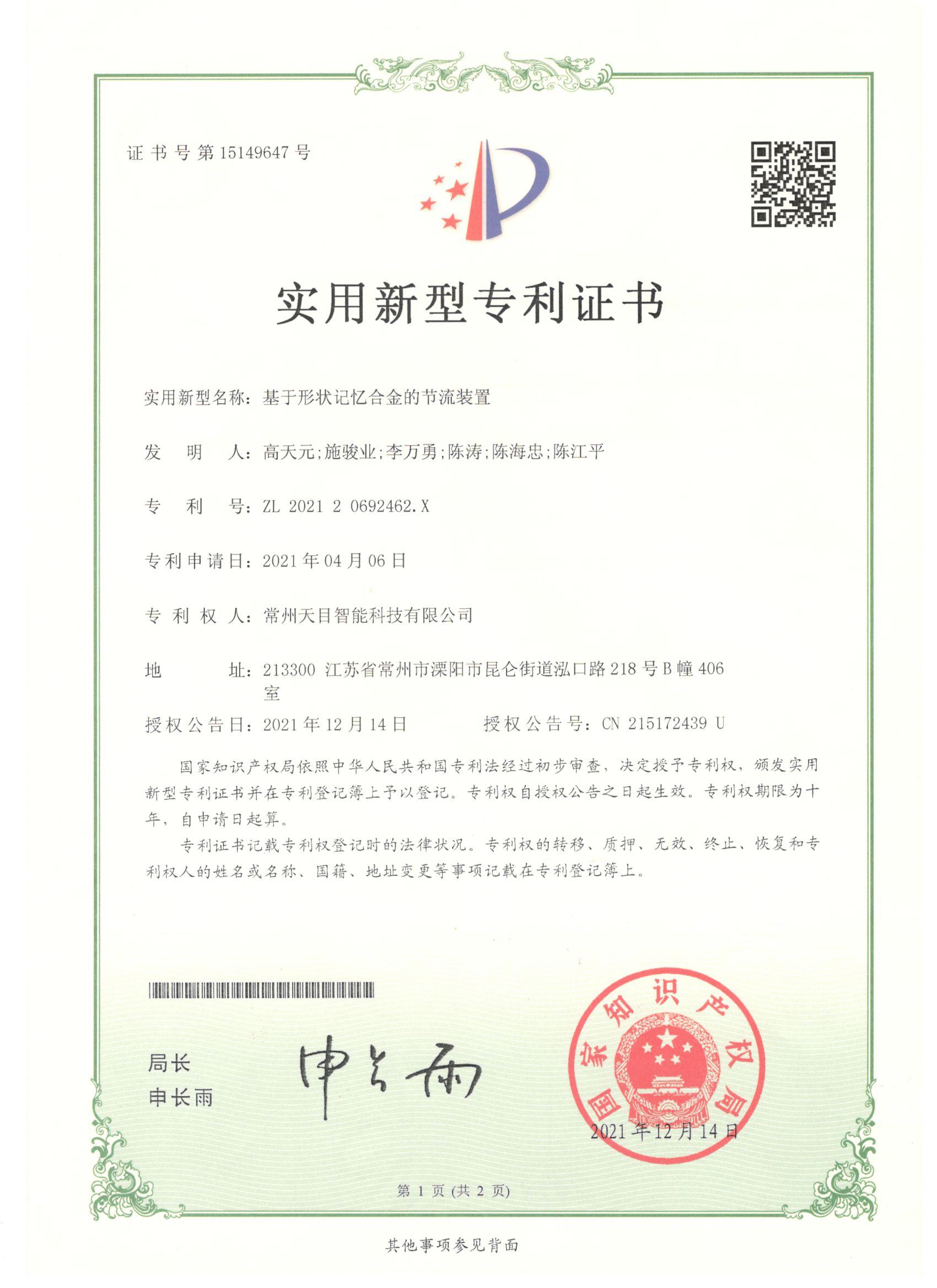

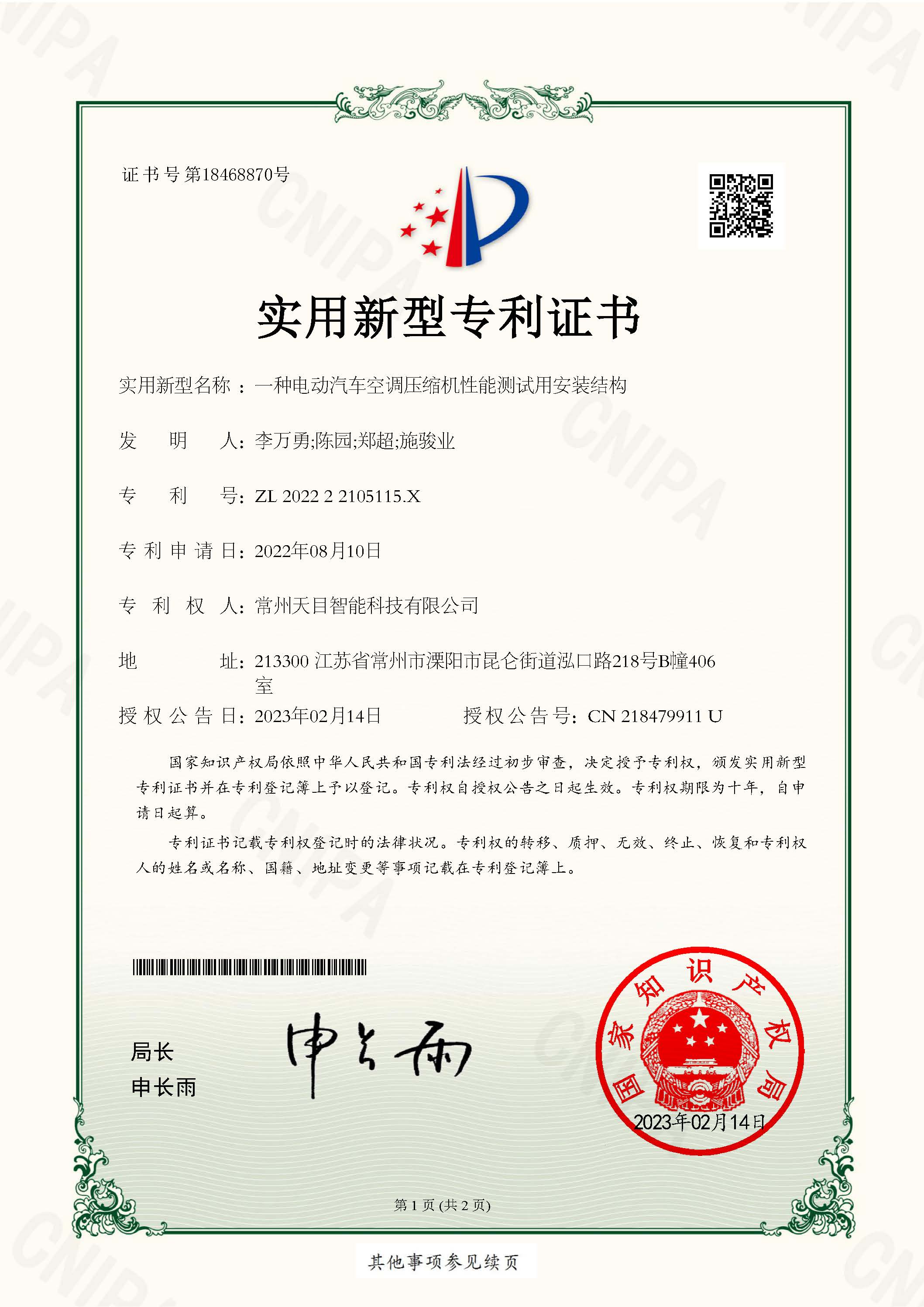

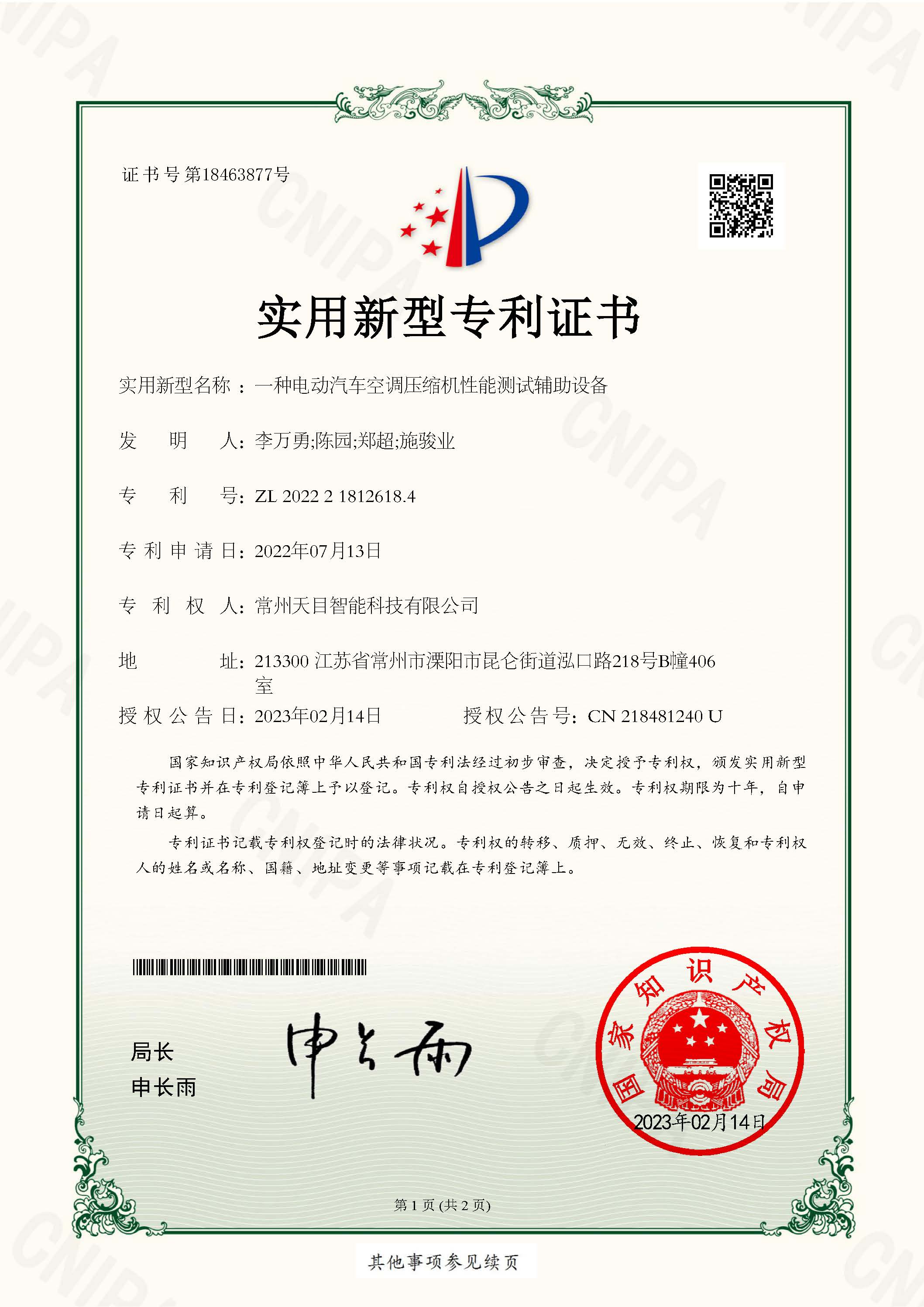

Changzhou Tianmu Intelligent Technology Co., Ltd. is rooted in Shanghai Jiao Tong University (SJTU) and its branch research institution - Liyang Research Institute of SJTU, which was established in 2020.

-

Energy Storage Thermal Management

-

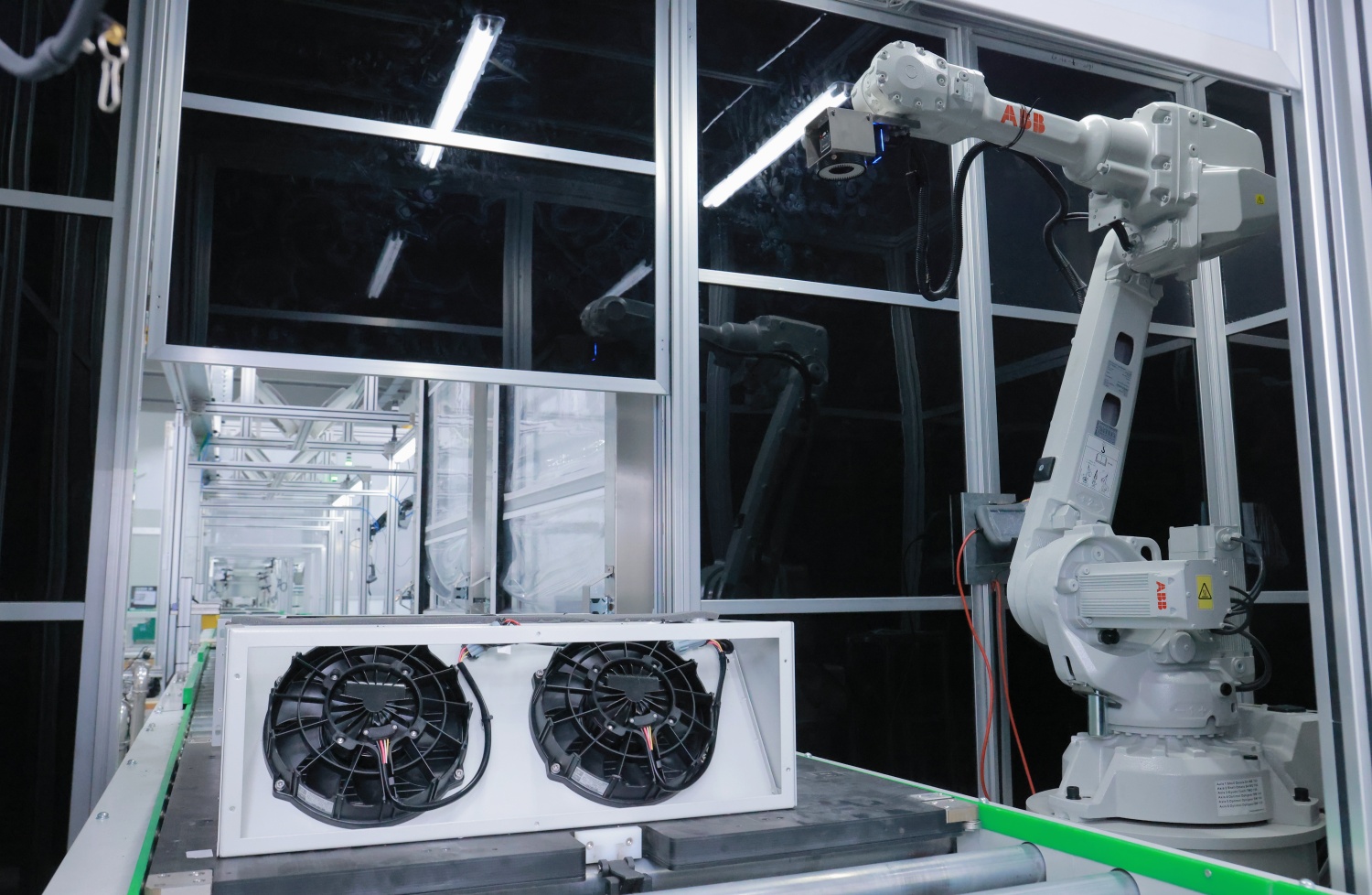

Thermal management testing equipment

- News

- Contact Us

EN

EN